Most of us assume that when we wear hearing protection, we are adequately protected from the noise around us. But is that a correct assumption? The only way to find out with certainty is to use a method of checking known as “Fit Testing”. The answer may surprise you.

SUMMARY

- The noise reduction rating – an unreliable guide

- Assessing the fit – all ears are different

- The case for fit testing ear plugs in Australia

- How are ear plugs fit tested?

- Real-ear attenuation at threshold (REAT)

- Microphone-in-real-ear (MIRE)

- Loudness balance

- What are the benefits of fit testing?

- More effective protection

- Preventing ONIHL

- Improving hearing conservation programs

- Eliminating the problem of over-protection

- Reducing compensation claims

- Summation

The noise reduction rating – an unreliable guide

Noise-induced hearing loss (ONIHL) is one of the most permanent and preventable occupational diseases worldwide. Hearing Protection Devices (HPDs), including single-use disposable earplugs, reusable earplugs, earmuffs and custom-moulded hearing protectors, provide protection from ONIHL for workers who are exposed to excessive noise levels.

Before any HPD can be sold in Australia, it must be evaluated in a test laboratory and labelled with a noise reduction rating (the Sound Level Conversion, or SLC 80). This mandatory rating measures the capability of a hearing protector to reduce the level of noise entering the user's ear. However, studies show that different wearers obtain varying levels of reduction from the same hearing protector. This means that the rating determined in the test lab, and specified on the packaging, is unreliable in predicting the actual noise reduction the user will attain in the workplace.

In reality, users of generic ear plugs rarely achieve the level of protection that is expected based on the rating label. Research has shown that in real-life situations, many workers achieve less than half of the noise reduction of the rating. While one worker using an earplug with an SLC80 of 33 may get 35 decibels of reduction, a second may get only 15dB and a third may get no reduction at all. Berger et al. reviewed 22 studies of how hearing protection is used in the real world by the end-user and found that earplugs provided an average of about 6 dB of sound reduction, while earmuffs provided a little over 14 dB reduction. Overall, the average attenuation that workers using earplugs received in the real world is often inadequate to meet even a modest goal of 10-15 dB of protection.

Assessing the fit – all ears are different

Why do many generic earplugs fail to provide the level of protection that they claim? Some of the factors that account for a reduced level of noise reduction from an HPD in the working environment include:

- The hearing protector itself, e.g. its shape, size, condition and age

- The concurrent use of other protective equipment such as safety glasses, helmets and hairnets

- The attitude of the user to hearing protection, e.g. lack of desire to fit them properly

- A poor fit of the device to the shape and size of the user’s ear canal

The proper fit of the hearing protection device to the user’s ear is vital for an adequate seal from a noisy environment. When it is not fitted properly, the HPD will not effectively protect the user from the noise.

The difference between the given rating of an earplug and the actual noise reduction attained by the user may vary widely because of the different ear canal sizes and shapes of users. Not only are all ears different, but ears continue growing at a rate of around 0.22mm per year, meaning that even custom moulded ear plugs may diminish in effectiveness after several years of use.

Hearing protection fit testing is undertaken to ensure the HPD is appropriate for the worker and the type of work involved. Two aspects are evaluated by fit testing:

- Is the HPD is effective for the particular noise environment?

- Is the HPD is effective for the particular user?

In many cases the answer is no, given that every person’s ear shapes and sizes are different, and many earplugs still used today are of the one-size-fits-all variety. Also, many people simply do not insert generic earplugs correctly. Individual technique in fitting earplugs is probably the largest variable in overall attenuation results. An inappropriate fit and poor insertion practises lead to a poor level of protection, compromising the effectiveness of the HPDs and probably exposing workers to harmful levels of noise.

The case for fit testing ear plugs in Australia

HPDs are considered a suitable control mechanism for noise protection in many environments. In Australia, the “AS/NZS 1269.3:2005 Occupational noise management – Hearing protector program” (“the standard”) specifies the requirements for the selection, use and maintenance of HPDs in noisy workplaces. The standard states that “the fitting of hearing protectors is an important part of the hearing protector program” which should preferably “be undertaken by an appropriately trained person with substantial knowledge of hearing protection”.

The fitting procedure outlined in the standard covers initial fitting and training, on-the-job fitting and demonstration, and follow-up. It is noted in the standard that “particular care is required with the fitting of earplugs, which if poorly fitted may provide little protection”. Additionally, the standard acknowledges that “the extent to which laboratory attenuation is approached in real-world workplace conditions depends on many factors including the degree of diligence in the implementation of a hearing protector program as described in this Standard.” Management responsibilities therefore include “evaluation of each person assigned to wear hearing protectors to determine if he or she is physically suited.” Furthermore, the Standard states that “the enormous diversity of hearing protectors (both earplugs and earmuffs, their wide range of attenuation and variation in their correct fitting) necessitates close attention to one-on-one fitting instruction, supervision, motivation and evaluation in workplace conditions.”

Note that the current Standard was published back in 2005, when fit testing technology was not as effective, nor as widely available, as it is now. However, because of the Standard’s strong emphasis on the need for management to evaluate that the supplied earplugs are providing suitable protection, a growing number of Australian industries are requiring workers to be fit tested by qualified personnel.

Determining whether workers have optimal real-world attenuation for their noise environment is critical to the success of an effective occupational hearing conservation program. These industries acknowledge that best practice is to ensure the right fit for any HPD; without fit testing, it becomes impossible to demonstrate that workers are being fully protected. For these reasons, fit testing of hearing protection in Australia is now mandatory on a number of sites and across various industries, including mining and oil and gas.

How are ear plugs fit tested?

Hearing protector fit-testing, also known as field attenuation estimation system (FAES), determines how effective a hearing protection device is for an individual when worn correctly. This is typically carried out using a fit-testing hardware and/or software system. There are a number of fit-testing systems currently available in Australia, some of which are brand-specific and some of which can test any in-ear HPD.

Fit testing measures the noise reduction an HPD provides for an individual worker and calculates that worker’s Personal Attenuation Rating (PAR). It identifies those at risk for developing hearing loss as a result of poor earplug fit while eliminating the need to de-rate the SLC80.

The three major field test methods used to measure the attenuation of HPDs are as follows:

Real-ear attenuation at threshold (REAT)

The most common method of fit testing, used by earplug manufacturers to test their earplugs as per AS/NZS 1270:2002 Acoustics – Hearing protectors, determines the quietest test tone a subject can detect without hearing protection and with hearing protection The difference between the two sets of measurements, called “real ear attenuation at threshold” (REAT), is an estimate of the protection provided by the ear plugs. However, the attenuation values determined in the laboratory are obtained from test subjects (20 subjects, 50% of whom are male), who are generally not representative of the actual workers who will be wearing them.

The REAT method was developed as a laboratory method and has been adapted for real-world applications. Individual fit-testing provides a vastly improved estimate of the real protection that workers can expect from their hearing protection devices. Most REAT systems use a subjective measure to determine auditory thresholds much like a hearing test where the subject indicates when sound is heard at various frequencies. For earmuffs this must be tested in an acoustic chamber, however for earplugs, headphones can be used, making the test easier for commercial use.

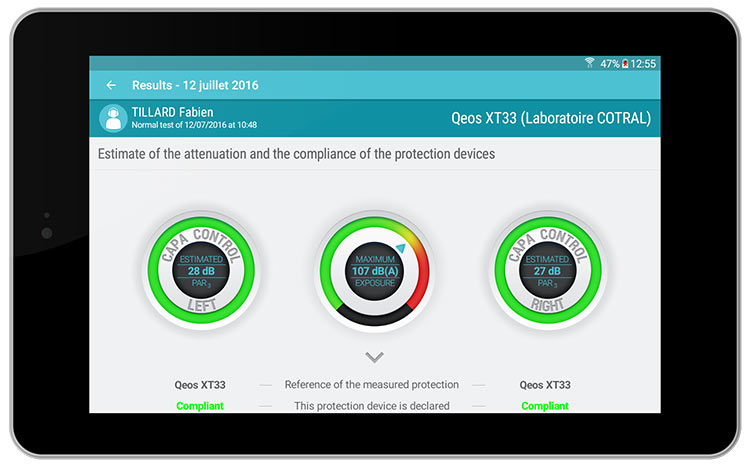

The CAPA© hearing protection fit testing system from Cotral Lab is a field REAT method that offers 2 types of tests, a ‘conventional’ test covering 7 audiometric frequencies and a ‘flash’ test of one randomly chosen frequency. CAPA© can test almost any brand of in-ear HPD’s, including disposable, re-usable and customised hearing protection.

Microphone-in-real-ear (MIRE)

Also referred to as F-MIRE (field microphone in real ear), attenuation is measured by placing a small microphone inside the ear canal while hearing protection is worn. Sound pressure levels (SPL) are measured inside and outside of the ear simultaneously and used to calculate a PAR.

Loudness balance

In this method, the subject listens to tones with headphones and "match" loudness between both ears until tones sound equally loud on both sides. Then an earplug is placed in one ear while the baseline procedure is repeated to match loudness in both ears. The procedure is repeated a third time so both ears are tested individually with earplugs. This calculates a PAR based on the loudness of the sound delivered to the unprotected ear when it matches the protected ear.

What are the benefits of fit testing?

Fit testing benefits both employers and employees alike.

For the employer, it assesses the suitability of the earplugs they are providing by comparing the actual attenuation achieved with attenuation expected from the label. It also fulfils regulatory requirements for training with documented results.

For employees, fit testing demonstrates the importance of hearing protection in the workplace, and helps employees select and compare protectors to find the best choice for their ears and specific noise environments. The end result is improved employee confidence in, and compliance with, the company’s hearing conservation program.

More effective protection

How can workers trust their hearing protection if they don't know how well it works? Testing to ensure that the ear plugs fit correctly and really do provide an adequate seal in the wearers ear, is the key outcome of fit testing.

Ear plug fit testing provides a formal metric from which management can determine whether employees are:

- receiving optimal protection for their noise environment

- require additional training on how to fit their ear plugs

- need to try a different model

The user's ability to fit an earplug may be the largest single variable in HPD performance. The wide range of attenuation provided by any given earplug is another primary reason for individual fit-testing of earplugs.

The importance of fit testing as a critical element of one-on-one employee training in the correct fitting of the earplug cannot be overstated. The more often a worker receives individual training in the proper use of hearing protectors, the higher the probability of a good fit.

Preventing ONIHL

The increasing availability and feasibility for companies to conduct individual fit-testing of earplugs is a growing trend in the prevention of noise-induced hearing loss. Many workplaces expose workers to loud noise that will damage hearing if suitable HPDs are not used. The need for individual fit-testing and intervention for those users with inappropriate levels of protection is evident in the continued hearing loss of noise-exposed workers.

Universal implementation of hearing protector fit-testing could help to reduce the incidence of hearing loss among workers who use poorly fitting HPDs. Fit testing focuses efforts on prevention of hearing loss rather than on mere compliance with occupational safety laws. Fit testing is gaining greater adoption by hearing conservation experts and by industry as a key tool in hearing loss prevention.

Improving hearing conservation programs

While many occupational hearing conservation programs have the best intentions to ensure that workers are using hearing protectors, the ultimate goal is to ensure that workers wear them properly 100 percent of the time when exposed to hazardous noise. No generalised rating scheme for hearing protectors can be effective without knowing how much attenuation individual workers actually attain.

The focus of a review conducted in 2011 described the individual fit-testing of earplugs as “an exciting new trend in hearing conservation” and a means to protect noise-exposed workers by improving training and documentation and evaluating the real-world effectiveness of HPDs.

For employers and their health and safety officers, fit testing records can help document that effective steps were taken to select appropriate hearing protections, train workers in their proper use, and to document a proper fit with a particular protector. These documented results are very useful for hearing conservation programs.

The scientists and practitioners developing and using earplug fit-test systems have reported various uses for individual fit-testing to improve hearing conservation programs by:

- Prioritising workers at risk for noise-induced hearing loss

- Identifying workers who need training on the correct insertion of the HPD

- Training the trainer how to teach appropriate earplug fitting technique

- Providing feedback to the users, allowing them to distinguish between a poor fit and a good fit

- Selecting the most effective HPD for an individual worker’s specific noise environment

- Identifying the most suitable HPDs to offer workers for the overall work environment

- Ensuring the worker is sufficiently protected from hazardous noise

- Documenting that the worker is sufficiently protected from hazardous noise

- Identifying cases of "overprotection", which can isolate workers from the environment, particularly hearing-impaired workers

- Complying with regulations and the necessary documentation thereof

- Evaluating the effectiveness of hearing conservation programs.

In a Best Practice Bulletin issued by an alliance between the National Hearing Conservation Association (NHCA) and OSHA, ear plug fit testing was endorsed as a recommended best practice in reducing occupational hearing loss as well as a metric to assess a hearing conservation program’s overall effectiveness. The bulletin also cited fit testing as a way “to match the employee’s hearing protector attenuation to his/her noise exposure level. This may be particularly useful in hearing critical jobs or for those with hearing impairment.”

Eliminating the problem of over-protection

A common mistake in noisy workplaces is the selection and wearing of a hearing protector with unnecessarily high attenuation, rather than choosing the most suitable protector for the noise environment. This may lead to a sense of isolation and difficulties with perception of sound, including warning signals. The standard states that in general, over-protection is to be avoided so as to minimise isolation and poor communication.

Overprotection could lead to failure to wear the HPD in the proper manner and during all times it is required; for example, the user might remove it in order to hear an instruction or have a conversation. Failure to wear the HPD during the entire exposure will significantly decrease the effective protection of the hearing protector; over a working day, periods of a few minutes’ unprotected exposure easily accumulate. Fit testing can identify workers who are over-protected and help identify a more appropriate level of protection for their environment.

Reducing compensation claims

Fit testing for ear plugs can be an invaluable tool in reducing compensation claims for noise-induced hearing loss at the workplace. Fit testing records can help document that effective steps were taken to select appropriate hearing protectors, train workers in their proper use, and to document a proper fit with a particular protector. This level of powerful documentation has been unavailable for many hearing conservation programs in the past.

Summation

In effect, the rating figure provided on the packaging is not a good indicator that the earplug will be effective in real world situations. While some users achieve the given level, many more do not, and for this reason it has been suggested that the rating provided should be regarded as nothing more than a rough estimate.

Assessing the fit of the earplug in the actual ear of the user is the only way to determine how much noise reduction the individual is actually attaining from the device and thereby ensuring that he or she is being sufficiently protected from excessive noise. Fit testing of hearing protection bridges the gap between the laboratory estimates of attenuation and the attenuation achieved by workers as they normally wear their protectors in the real-world.

Therefore, it is essential to know how well HPDs work on individuals, and the only way to make that determination is to test HPDs on those individuals. As previously stated, the rating provided on the packaging is not indicative, nor a good predictor, of the HPD’s performance on individual users. It is a useful comparative tool to indicate that Product A is capable of more or less protection than Product B, but to determine how well HPDs work on individual users, HPDs must be tested on those users. Relying on the rating, even if it is de-rated, to determine how much protection an individual is obtaining from an HPD is not good practice. The wide range of attenuation provided by any given earplug is a primary reason for individual fit-testing of earplugs.

Studies and sources referenced in this article:

Australian Standards AS/NZ 1269.3:2005 Occupational Noise Management, Part 3 Hearing Protector Program.

http://www.noiseandhealth.org

https://ohsonline.com